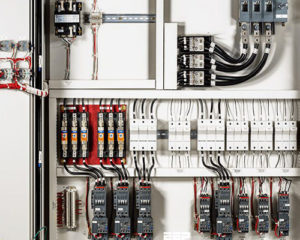

Control Panel

ATS offers best technology & long experience building high quality control panels and electrical control systems. While ATS maintains long standing partnerships with leading technology sup-pliers, we offer technology solutions that best meet our client’s needs. As one of the nation’s largest manufacturers of electrical control solutions, ATS offers high value panels, short lead times, and exceptional quality. Our manufacturing operations are well known & listed in each segment of user, and recognized for a long-standing commitment to safety and operational excellence. Our world-class manufacturing space is flexible to accommodate a wide range of projects and thus allows us to decrease lead times, and expedite control panel deliveries without negatively impacting quality.

Designing and developing control panels for industrial and utility applications is a multi-step process that requires attention to detail. Build to print; we have produced virtually every type of panel – low voltage control panels, motor control panels, substation panels including simplex, duplex and freestanding enclosures, modular racks, as well as entire substations.

As a first step, we review all customer documentation and identify potential inconsistencies that can become an obstacle to success. Our engineering services group creates detailed, dimensioned control panel layout drawings, bills of materials, including quantities and part numbers; and full machine, process, and panel one-line diagrams and schematics.

Once approved, we move into full production following our time tested quality procedures every step of the way. Our workmanship and attention to detail ensure that shipments are of the best quality and made exactly to your specifications.

As a first step, we review all customer documentation and identify potential inconsistencies that can become an obstacle to success. Our engineering services group creates detailed, dimensioned control panel layout drawings, bills of materials, including quantities and part numbers; and full machine, process, and panel one-line diagrams and schematics.

Once approved, we move into full production following our time tested quality procedures every step of the way. Our workmanship and attention to detail ensure that shipments are of the best quality and made exactly to your specifications.

Design & Documentation

- Control panel layout and construction drawings

- Itemized bills of material

- Electrical schematics

- Elementary and point-to-point wiring diagrams

Electrical Assembly

- Low voltage control panels

- PLC panels

- Combination starter panels

- Customized MCCs

- Remote Terminal Units (RTU)

- Custom VFD packaging

- Protective relay switchboards

- Communication racks

- Transformer protection

- Capacitor bank panels

Mechanical Assembly

- Instrumentation / analyzer racks and skids

- Pneumatic assemblies

- Hydraulic assemblies

- Copper, stainless steel, and polyethylene tubing

- O2 cleaning

- Light structural fabrication

Testing & Quality Checks

- Process testing

- Final testing

- Test reports

- Packing details

- Documentation